Starting in November 2025, a new rule begins across China that tracks every lithium-ion battery made in China through its full life. The Chinese market regulator gave final approval to these coding guidelines to boost both safety and control measures. Tracking each unit becomes possible thanks to unique identification set by Chinese standards. Instead of waiting for problems, oversight now shifts toward early detection using systematic labeling. Safety doesn't come only after incidents - prevention builds in from the start. How batteries are made, used, and handled changes with this step. Clear codes replace guesswork during inspections or recalls. Oversight grows stronger without needing extra layers of bureaucracy.

A single ID tag goes on each fresh battery made in China. Every kind falls under this rule - cells, modules, packs, clusters, even turnkey systems. Starting at manufacturing, ending at reuse, one code tracks it all. That trail helps follow what happens to units later. Oversight gets easier when every piece shows its history.

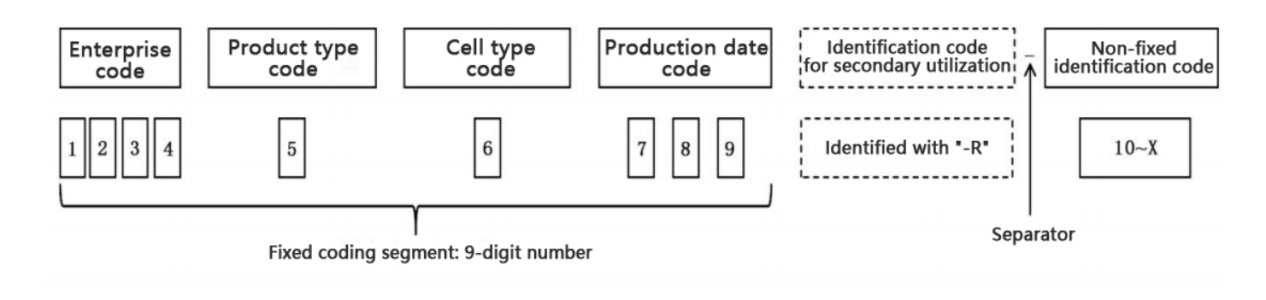

Starting off, Chinese standard lithium-ion battery codes split into two main pieces. One part stays the same every time. The other changes depending on specifics. Look at the image nearby to see how it's laid out. Between these sections, a dash "-" sits in between them. That mark separates what's constant from what varies.

Just so you know - if that Chinese lithium-ion battery has been reused or given a new role after its first life, slap in a "-R" tag right after the standard code part but before the variable ID bit.

Schematic Diagram of the Coding Structure

for Standard-Sized Lithium-ion Batteries in China

● Enterprise Code <1234>

Four digits make up the Enterprise Code, chosen freely by each business. These symbols come from numbers and capital letters - just skip I and O. A short explanation tags along when submitting it. Picking them? Mix zeros through nines with available alphabets. Not every letter joins, mind you. Defined internally, then shared officially. What fills those slots stays within that set list. Submission includes what the code stands for. Letters blend into figures without fixed order. Each Chinese lithium battery manufacturer sets its own pattern.

A look back at older battery cell labels shows what was used before updated rules took effect. These examples stand as a guide to earlier formats:

|

No. |

Brand Name |

No. |

Brand Name |

|

001 |

CATL |

02C |

Lishen Battery |

|

002 |

ZTE |

02K |

Great Power |

|

004 |

Far East Battery |

03N |

Wanxiang A123 |

|

005 |

BAK Battery |

03H |

Gotion High-tech |

|

010 |

Godsend Power |

04Q |

EVE |

|

031 |

Soundon New Energy |

07H |

Hithium |

|

060 |

Henan Lithium Power |

08L |

TFE (Tafel) |

|

064 |

Farasis Energy |

08M |

Anchi New Energy |

|

081 |

REPT |

0B5 |

CALB |

|

090 |

SVOLT |

0D9 |

BYD |

|

00P |

Sunwoda |

00G |

ETC |

● Product Type Code <5>

| Sequence | Digits | Category Name | Description (Representative Info) | Code & Definition |

| 5 | 1 | Product Type Code | Battery Cell | C |

| Consumer Battery Module | A | |||

| Consumer Battery Pack | B | |||

| Consumer Battery System | D | |||

| High-Power Battery Module | M | |||

| High-Power Battery Pack | P | |||

| High-Power Battery System | S | |||

| Low-Power Battery Module | E | |||

| Low-Power Battery Pack | F | |||

| Low-Power Battery System | G | |||

| Energy Storage Battery Module | H | |||

| Energy Storage Battery Cluster | J | |||

| Energy Storage Battery System | K |

● Battery Type Code <6>

| Sequence | Digits | Category Name | Description (Representative Info) | Code & Definition |

| 6 | 1 | Battery Type Code | Lithium Manganese Iron Phosphate Battery (LMFP) | A |

| Lithium Iron Phosphate Battery (LFP) | B | |||

| Lithium Manganese Oxide Battery (LMO) | C | |||

| Lithium Cobalt Oxide Battery (LCO) | D | |||

| Nickel Cobalt Manganese Ternary Battery (NCM) | E | |||

| Nickel Cobalt Aluminum Ternary Battery (NCA) | F | |||

| Lithium Titanate Battery (LTO) | G | |||

| Other Types of Batteries | Z |

● Production Date Code <789>

<7> stands for the year it was made. When you see <8>, that is how they mark the month. The number <9> tells which day came off the line. Rules for these codes follow a set pattern for year, then month, then day. Marking when something is built uses this order every time. For example: The code for January 1, 2025, is F11.

|

Year |

Code |

Year |

Code |

Year |

Code |

Year |

Code |

|

2025 |

F |

2035 |

S |

2045 |

5 |

2055 |

F |

|

2026 |

G |

2036 |

T |

2046 |

6 |

2056 |

G |

|

2027 |

H |

2037 |

V |

2047 |

7 |

2057 |

H |

|

2028 |

J |

2038 |

W |

2048 |

8 |

2058 |

J |

|

2029 |

K |

2039 |

X |

2049 |

9 |

2059 |

K |

|

2030 |

L |

2040 |

Y |

2050 |

A |

2060 |

L |

|

2031 |

M |

2041 |

1 |

2051 |

B |

2061 |

M |

|

2032 |

N |

2042 |

2 |

2052 |

C |

2062 |

N |

|

2033 |

P |

2043 |

3 |

2053 |

D |

2063 |

P |

|

2034 |

R |

2044 |

4 |

2054 |

E |

2064 |

R |

Year code

|

Month |

Jan |

Feb |

Mar |

Apr |

May |

Jun |

Jul |

Aug |

Sep |

Oct |

Nov |

Dec |

|

Code |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

A |

B |

C |

Month code

|

Date |

Code |

Date |

Code |

Date |

Code |

|

1 |

1 |

12 |

C |

23 |

P |

|

2 |

2 |

13 |

D |

24 |

R |

|

3 |

3 |

14 |

E |

25 |

S |

|

4 |

4 |

15 |

F |

26 |

T |

|

5 |

5 |

16 |

G |

27 |

V |

|

6 |

6 |

17 |

H |

28 |

W |

|

7 |

7 |

18 |

J |

29 |

X |

|

8 |

8 |

19 |

K |

30 |

Y |

|

9 |

9 |

20 |

L |

31 |

0 |

|

10 |

A |

21 |

M |

— |

— |

|

11 |

B |

22 |

N |

— |

— |

Data code

● Non-fixed Identification Code <10~X>

A sequence made up by the company goes here, along with some written details about it. Pick symbols only from numbers and capital letters, but skip "I" and "O". Inside this part, there has to be a serial number for manufacturing - other tags like model type, line used, who supplied materials, or which machine ran can also go in. Twenty characters is the longest it should get. For tracking output, better to build that serial bit just with digits or capitals on its own.

Hot News

Hot News2026-01-16

2026-01-08

2025-12-04

2025-11-14

2025-09-08

2025-07-28

● Fill out the form with your needs, we will get back to you within 24 hours.

● Need immediate help? Call us!